2008-tool-cyclone-dust-collector

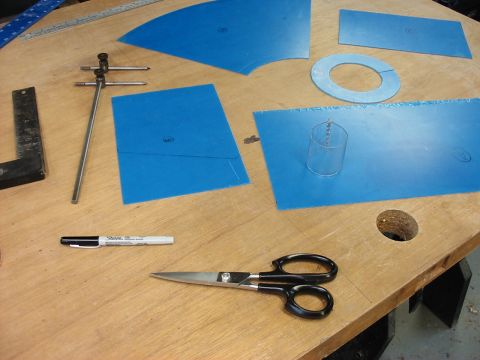

cyclone dust collector on the cheap well if you wondered where i have been the past few months, this is the main reason! i have been working on my low cost cyclone shop dust collection system, and i am very happy to tell all of you that it works, and works WELL! a few months back i decided i wanted to make a dust collector, and began my research. early on i determined that a cyclone was the thing for me, and read lots and lots of documentation on how to properly build one. much of my labor and costs were spent on things i did not need, and couldn't make work the way i wanted. in the end my cyclone design was very simple and cost effective, and i will be using a similar design on my next version. my cyclone sizing is undersized for my shop vac, and while it still works well, could be larger despite the calculations and recomended sizing. the absolute most important thing learned from this project: make certain that all seals around the lower dust bin are completely air tight, this will prevent updraft thereby disrupting the cyclone and push dust up into the top vac section. i was able to correct all my problems with a $3.22 bag of rubber weather seal! a dust collector is really only half the battle, each tool has to be connected to ducting effectively! my table saw and bandsaw both have effective dust collection hoods, however my jointer and drill press do not and will require customization to effectively collect chips. my design used a shop vac, some ducting tin, pvc, tape, adhesive, wood, and a garbage can. relatively speaking it was cheap, effective, and a definite conversation starter!